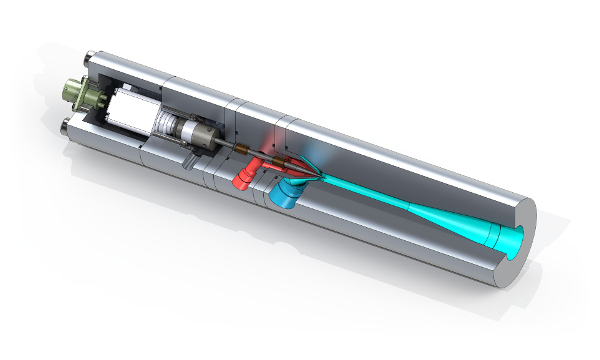

How It Works

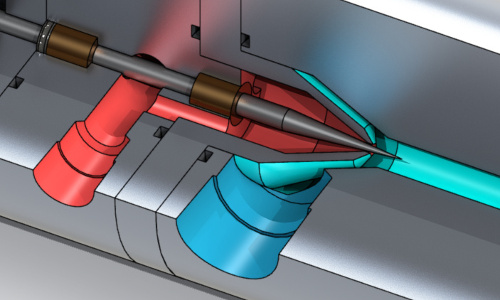

The Sonijector operates on the principle of a venturi tube. High pressure hydrogen gas is fed to one end (shown in red), and as it flows through the nozzle, it accelerates to supersonic speed and develops very low pressure. With proper design, the throat pressure is low enough that it can draw unused hydrogen from the fuel cell stack into the ejector's secondary inlet (dark blue) and return it to the stack (outlet in light blue).

The Sonijector controls the flow rate of hydrogen to match the demand from the fuel cell (low when idling, high when accelerating a vehicle rapidly) by means of a tapered needle which runs along the axis of the ejector and terminates at the throat. By moving the needle in and out of the throat with a stepper motor, the right amount of hydrogen can be metered to the stack. The needle’s position is continuously monitored and adjusted by a stepper motor which is driven by a feedback signal from a pressure sensor at the stack inlet. The stepper motor is driven by an electronic control unit in an IP67 rated housing.

The Sonijector has been successfully implemented within the University of Delaware’s fuel cell bus fleet, and has delivered flawless performance for several years. Sonijector prototypes are being field tested by automotive OEMs worldwide. The Sonijector is available in various sizes for installation in forklifts, motorcycles, cars, buses, trucks, and stationary power systems.